PACKAGING, INSPECTION, WRAPPING, LABELLING AND CODING MACHINE SOLUTIONS FOR THE MEAT AND POULTRY

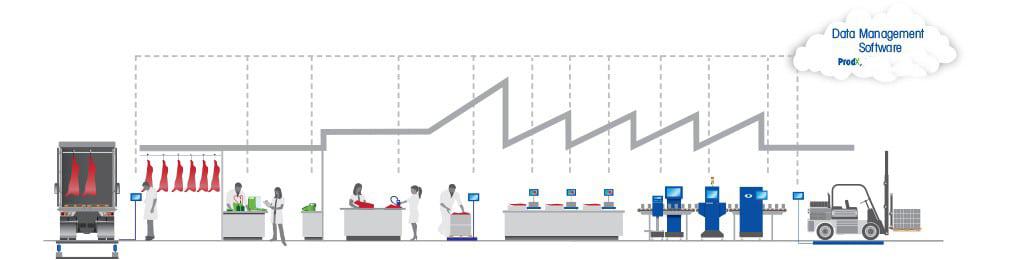

Al Thika Packaging is the exclusive supplier who is capable of offering a wide range of packaging, inspection, weighing and labelling machinery solutions for the meat and poultry sectors.

The meat and poultry sector requires flexible packaging solutions that range from cost-effective hygienic packaging for complex packaging ensuring excellent presentation and extended shelf-life (MAP).

Al Thika Packaging is aware that the success of its clients depends on the quality of their products and protective packaging. We draw from more than 25 years of experience supplying packing machine, stretch wrapping machine, coding printer weigh price labeller to guarantee our clients the highest quality solutions for the commercial success of your products and brands.

Al Thika Packaging is aware that the success of its clients depends on the quality of their products and protective packaging. We draw from more than 25 years of experience supplying packing machine, stretch wrapping machine, coding printer weigh price labeller to guarantee our clients the highest quality solutions for the commercial success of your products and brands.

MEAT AND CHICKEN PACKAGING MACHINE SOLUTIONS

ULMA Packaging – MAP – SKIN – VACUUM

ULMA offers the widest range of packaging solutions on the market for the meat & poultry sectors, from solutions for catering distribution to final retail distribution. ULMA offers packaging solutions between five different packaging systems: Thermoforming, Traysealing, Horizontal Flow Pack (HFFS), Vertical Flow Pack (VFFS) and Stretch Film, each with their unique ability to customise the package presentation and shelf-life needs of the product.

PRODUCT INSPECTION SYSTEM SOLUTIONS

Mettler Toledo

Cost pressure and short shelf life combined with complex regulatory requirements impact meat and poultry manufacturers. Packaging trends and market requirements for wider product variety add additional pressure. Mettler Toledo’s solutions are designed to make it easier to detect smaller contaminants, reduce product waste, minimise false rejects, maximise uptime and meet compliance needs.

Whatever your product format and material handling method at the designated critical control point – loose or bulk, pumped,

fresh , frozen, or packaged – we have a product inspection solution to meet your needs.

CODING AND MARKING PRINTER FOR MEAT AND CHICKEN

Markem Imaje printer

Markem Imaje provides the reliable coding that you need for all aspects of the meat and poultry industry. Whether you are printing best before dates, ingredients, logos or barcodes , Markem Imaje machines will produce the highest quality codes, even in your demanding environments. Powered by our intuitive CoLOS software, Markem Imaje hot melt, print & apply and laser technologies will minimise operator errors while increasing your sustainability and reducing your total cost of ownership (TCO).

WEIGH PRICE LABELLER

BAG-IN-BOX CASE ERECTOR SOLUTIONS

COMBINING PACKING- & WEIGHT BASED FILLING TECHNOLOGY FOR A FULL AUTOMATIC SOLUTION

Feeding this line with your products straight from the bulk container, piles of your crates and prefabricated bags, it provides you with your product packed in a closed bag in a crate, ready to be transported!

TEMPERATURE & HUMIDITY DATA LOGGER

Tiny Tag from Gemini data logger

Data loggers are used extensively in the meat and poultry industries where it is vital that temperatures are accurately maintained at specified levels and recorded for ongoing verification.

Data loggers are used in processing, cooking, pasteurisation, cooling and freezing. They are used throughout cold chain storage and distribution; in refrigerators, freezers and chilled display cabinets; and during sterilisation procedures and in industrial dishwashers.

Comments

Post a Comment